A site that is approaching with a resurrection visual with wear tires and craftsmanship

Site exploration

関西 (更新)About Nikkei article use service

If you would like to share articles in a company, reprint, copy, and print order, please see the link.

詳しくはこちらWhen an old tire that glows black begins to rotate, a new groove is stuck without any disturbing, and is reborn like a new one.This is a re -styling manufacturing process called "Ritred", which reuses the surface of the worn tire and reuses it.It is said that about 70 % of the tires can be used again, so if you repeat retred twice, the amount of rubber used for raw materials and the carbon dioxide (CO2) emissions will be reduced by half compared to manufacturing three new ones.

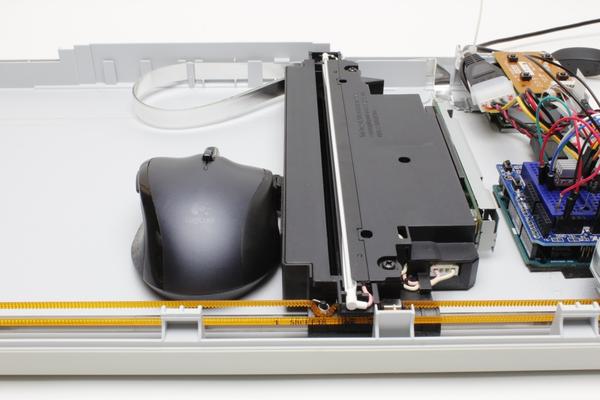

In a corner of Suminoe -ku, Osaka, there is "Bridgestone Tire Remarks Center Osaka" established by Bridgestone in 2013.There are about 30,000 tires that are reborn here.There are few automated processes in the factory, and it is a number of steady manual work that supports advanced manufacturing technology.Workers will process the "custom" process according to each tire, such as shaving the worn grooves and the damage to the damaged parts by stepping on a stone.

Above all, the process of pasting the rubber in contact with the road surface on the tires is condensed with precise craftsmanship.The point for winding it is to identify the required length and exact position.Even if you measure using a device, the number of mm errors is not unusual.Even if the tires of the same size are applied in advance based on a certain standard, the roundness of the circumference and cross sections differs one by one.The ultimate point is the sense of human eyes and hands.

The key to cultivating this feeling is on -site experience.The company has a unique technical certification system to acquire skills, but it will take a year as early as possible to accurately perform this process.Ryo Yokote (51), who has a nine -year career, says, "As you repeat the failure on the spot, you will be able to have a connoisseur of how many extra you can leave."

In order to bind the pasted rubber to the tire, it takes three and a half hours to put it in a cylindrical device and apply sulfur, 105 degrees heat and pressure.Finally, retred tires are born after a strict inspection process.The autumn season, which is about to snow, is a busy season.Orders to replace the surface for winter for winter, and the factory continues to be in full operation.

According to the Rehabilitation Tire National Council, half of the truck buses in Europe and the United States are retred tires, but only about 20 % in Japan, where "new orientation" is strong.As the conversion to the circular economy (circulating economy) working on recycling and recycling is progressing, Bridgestone also positions retred as a growth field, and has 13 manufacturing bases nationwide.Among them, the center is the only facility in a group that can consistently perform "reuse" of the recovered wear tires and "recycle" that converts abandoned tires with fuel.

On the other hand, the user's awareness goes to safety, but Mr. Motoyoshi Nakano, director of the center sales headquarters, said, "Customers who have seen the production site have received a high reputation for being relieved if they have such eyes and hands.There is a response.Before sending the reborn tires, apply a new black paint just like a new one.It is a consideration to make the new and old borders unique to retred.The wearing tires are added to the last effort and run for a new road.

(Keiki Kashiwara)

アプリで開くすべての記事が読み放題

有料会員が初回1カ月無料

About Nikkei article use service

If you would like to share articles in a company, reprint, copy, and print order, please see the link.

詳しくはこちらRelated Links

Related topic

Following the topic will make it easier to check and read new information.

Related article

Related companies and industries

企業:Related keywords

![[Sumida Aquarium] November 11th is "Chinese Eel Day" "Gather! Connect! Chinese Eel Festival 2020"](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/28/6eacd09bd972d65c8e0a17147173d1ec_0.jpeg)

![[Celebration 10th Anniversary] “Stationery Shop Grand Prize 2022” announced! The grand prize is Sakura Crepas "Ball Sign iD Plus" 549 latest items selected by professionals](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/28/59f09e884c15a54929745f8b7cfa05ad_0.jpeg)