Ocean Plastic Mouse is born from a unique resin development collaboration

Elliott Smith

*This blog is based on an abridged translation of “Collaboration on unique resin spurs creation of the Ocean Plastic Mouse” published on October 7, US time.

I never thought that something as small as a mouse could have such a big impact on Microsoft's sustainability efforts. The reason for this was the desire to contribute to the creation of a better society and the use of plastic PET bottles.

According to the National Ocean Service, scientists estimate that there are over 8 million tons of plastic in the ocean. Some studies have calculated that there will be more plastic than fish by 2050, demonstrating the enormous impact on the environment. So Microsoft's product and engineering teams were working on a big undertaking to put this plastic waste to good use in new ways.

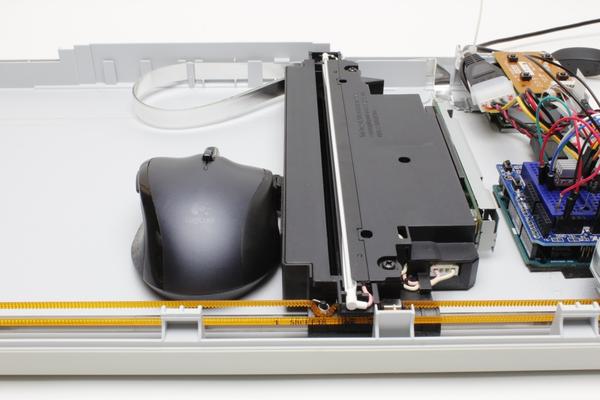

The development of the Microsoft Ocean Plastic mouse began with a question posed by a team of people intent on solving a difficult problem.

“We all wondered if we could make resin from marine plastics to reduce our environmental impact,” says Patrick Gall, senior designer on the Windows and devices design team. Gaule) speaks. “I started by giving shape to this idea. I did not know"

Plastic resin is made by breaking down hydrocarbons into smaller pieces when heated. Synthetic plastics contain polymers in their backbone components. Polymers are composed of repeating covalent units called monomeric residues. This polymer has specific characteristics that make it suitable for PET bottles, caps, packaging and other common plastic materials. Pellet-shaped or bead-shaped polymer resin is put into a mold and reborn as a product.

As part of Microsoft's commitment to zero waste by 2030, the team received an internal sustainability grant to start developing materials, focusing on using marine plastics for the resin on the mouse surface. . There are several products on the market made from marine plastic collected about 30 miles from waterways and shores. But making resin from marine plastic that has been verified by a third party as having been collected or washed ashore from the ocean or the waterways leading to it is a breakthrough.

“We wanted to do something different,” says Corinne Holmes, environmental compliance director for Windows and Devices. “I wanted to go beyond just using what was still clean. This plastic wasn’t collected from a collection bin on the beach. It was what was done.”

![[Latest in 2022] Explanation of how to register DAZN for docomo with images | 31 days 0 yen free trial reception until April 17](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/28/22149d541c51442b38a818ab134a8cf0_0.jpeg)

!["Amaho no Sakuna Hime" celebrates its first anniversary. The Ministry of Agriculture, Forestry and Fisheries moved to allow you to experience rice farming in a depth unparalleled in the history of games.A rice farming action RPG with over 1 million units shipped worldwide [What day is it today? ]](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/28/378f9ee978fe8784d8ab439d041eee85_0.jpeg)