Points from program check to continuous operation: NC basic knowledge 6

Before entering continuous operation, run the NC program to see if there are any errors in the content of the program and the correction value such as the work coordinate system.In addition, we will also check whether the product and parts that meet the request of the machine drawing can be processed by performing trial processing, and whether the optimal conditions are set.I will explain the points from program check to continuous operation.

Download technical materials now!(Login)

Lottery

1.Program check

If there is an error in the created NC program or the set correction value, the tool may interfere with the work, jigs, tables, etc. and may damage the tools and machinery.Therefore, execute the program to check if there is any mistake.Checking methods include checking by drawing function and air cut (empty operation).

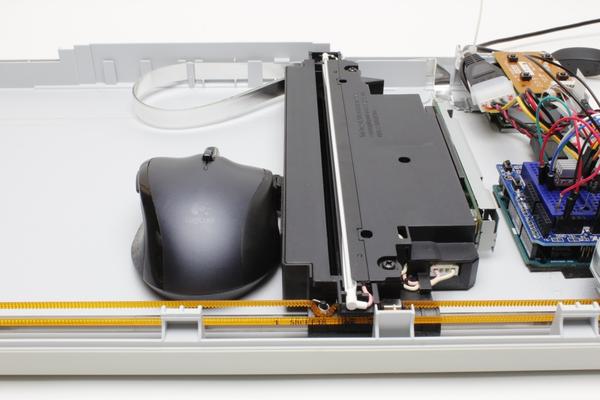

Explains three switches: mode selection of machine tools, NC function selection, and override to use when performing program checks.Figure 1 shows the mode selection switch.This is the first switch to select what you want to do when operating an NC machine tool.Here, only the switches related to autonomous driving and handle mode are explained.

図1:モード選択スイッチ・メモリ

メモリに登録されているNCプログラムを呼び出し、自動運転(メモリ運転)をするモード。

・MDI

NC操作盤から入力したプログラムを1回だけ実行できるモード。実行後、プログラムは消去される。簡単なプログラムを確認したい場合などに使用。

・テープ

外部入力機器を使ってプログラムを転送しながら運転(DNC運転)するモード。

・ハンドル

手動パルス発生器のハンドルを回すと、軸選択スイッチで選択した軸が移動できるモード。

Figure 2 shows the NC function selection switch.

図2:NC機能選択スイッチ・シングルブロック

プログラムを自動運転するとき、起動ボタンを押すごとに1ブロックずつ実行させる機能。

・オプショナルストップ

プログラム中に「M01」の指令があると、そのブロックで機械が一時停止する機能。再度、運転を開始するときは、起動ボタンを押す。この際、機種により主軸の回転やクーラントが再起動するものとしないものがある。プログラムチェック時や寸法チェック、切りくずを取り除くときなどに使用。

・ブロックデリート

プログラム中に「/」の指令があると、「/」からそのブロックの終了(EOB)までを無視する機能。

・ドライラン

プログラム中で指令された送り速度が無視され、手動送り選択スイッチで設定された速度で軸移動が行われる機能。プログラムチェック時の時間短縮をしたいときに使用。

・マシンロック

すべての軸移動がロックされて動かなくなる機能。画面の座標表示は指令通りに変化する。プログラムチェック時など、軸移動をしたくないときに使用。マシンロックを完全に解除する際は、このボタンを無効にして手動で機械原点復帰を行う。

Figure 3 shows an example of an overlide switch.The left is for fast forward adjustment, and the right is for cutting forward adjustment.In addition to these, there is also an override switch for the spindle rotation speed.For fast -forward adjustment, adjust the rate of the fastest sending speed of the machine tool.For cutting forwarding adjustment, adjust the ratio to the cutting speed of the program commanded by the program.When checking the program, minimize before pressing the startup button, check the safety before raising it.

図3:オーバーライドスイッチNext, I will explain the drawing function and the program check using the air cut.The program to be checked is explained as a memory registered.

1) Check with drawing function

Check using the drawing function of NC machine tools.Call and check the program registered in the memory, so use it in memory mode.In the drawing check, you do not need to move each axis, so apply a machine lock.Also, select a dry run to efficiently check.The single block switch will be released as soon as the machine lock is effective.No coolant is required.Figure 4 is an example of the drawing function of the NC lathe.

図4:描画機能の一例(NC旋盤)2) Check by air cut

Do not process the work, but check the trajectory of the tool. In the NC lathe, the work is usually removed from the chuck and driving. At the machining center, the J -Axial -directional work coordinate system is shifted to the plus side. No coolant is required. In the memory mode, select the dry run and a single block. While running the program one block, check if the tools are moving with the correct coordinates. The coordinates of the tools in the work coordinate system are displayed in the "absolute coordinate", and the remaining movements while moving tools are displayed in the "remaining movement amount" column. You can also check the modal information such as processing conditions and correction number on the NC screen. Also, when each tool approaches the work, check the scale whether various corrections are correct. At this time, switch to handle mode for safety.

Fig. 5 is an example of a 50mm shift of the work coordinate system on the plus side of the Z axis.The correction value entered in the common correction column is added to all the correction values of G54 to G59.

図5:ワーク座標系原点のシフト例(マシニングセンタ)2.Trial processing and evaluation

After the program check, try the first one.Here, it is necessary to judge the suitability of the processing conditions.If you have trouble after entering continuous operation, time and cost loss will be large.

NC machine tools are covered with a cover, and many of them are processed with coolant, so you can hardly check the cuts and sparks during processing.Therefore, it is necessary to judge the sound and vibration during processing, the state of the edge of the blade after processing, the dimensions accuracy of the processed product, and the surface roughness.We may check the main shaft load road meter.

If you put the M01 in each NC program process and enable the optional stop switch, you can check the processing status after each process.In addition, the single block function is used as necessary.The override switch is 100%for the spindle rotation and cutting -by -cutting adjustment, and the fast -forward adjustment is kept smaller in consideration of safety.If you feel that the setting conditions are too fast during the processing, adjust the override switch and correct the program after processing.

In order not to waste the work, adjust the finishing function to make it a little larger with the correction function.After that, measure dimensions, re -correct the dimensional tolerance, and finish the finish again.

3.Continuous operation

Trial processing will be performed, and if there is no mistake in the NC program, processing conditions, and various correction values, it will enter continuous operation.If the tools are worn for a long time with the same tool, regular dimensions are required so that defective products do not occur.

Continuing is published in PDF for storage.Please download and see from the following.

4.Equipment to produce accuracy

Published in PDF for storage.Please download and see from the following.

![[Osaka Marriott Miyako Hotel] Plenty of cheese! Italian buffet held company release | Nikkan Kogyo Shimbun electronic version](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/28/1061eb31530c979d7b766ae1877b113a_0.jpeg)